Increase Performance With Aftermarket Components: an Overview for Heavy Machinery Owners

Advantages of Aftermarket Components

Owners of heavy equipment can appreciate numerous benefits by going with aftermarket components over original tools maker (OEM) components. Among the main advantages is expense savings. Aftermarket components are commonly much more economical than OEM components, enabling equipment owners to decrease repair and maintenance expenses without compromising on quality. In addition, aftermarket components frequently come with service warranties, ensuring that buyers are safeguarded in instance of any type of flaws or concerns.

Because aftermarket makers specialize in generating specific components, equipment proprietors have access to a wider array of choices to match their requirements. Aftermarket components are understood for their top quality and reliability, with numerous conference or surpassing OEM criteria.

Last but not least, choosing aftermarket parts can likewise result in faster repairs and minimized downtime. With simpler availability and fast delivery alternatives, equipment proprietors can obtain their tools up and running again quickly, minimizing interruptions to their procedures.

Picking the Right Aftermarket Components

When considering aftermarket components for hefty machinery, it is vital to focus on compatibility and high quality to make sure optimum efficiency and long life of the equipment. Picking the appropriate aftermarket parts can be a crucial decision for hefty equipment owners as it directly impacts the performance and dependability of their devices.

Second of all, high quality needs to never be endangered when picking aftermarket parts (aftermarket construction parts). Opting for high-quality components makes sure resilience, dependability, and total performance of the machinery. It is a good idea to resource aftermarket components from trustworthy makers or providers recognized for their quality requirements

Furthermore, thinking about aspects such as service warranties, client evaluations, and compatibility with existing systems can even more help in making the best selection. By focusing on compatibility and high quality when picking aftermarket components, heavy equipment proprietors can boost the performance and long life of their tools.

Setup and Maintenance Tips

For efficient procedure and long life of hefty equipment, correct setup and normal maintenance are extremely important. When setting up aftermarket components, make sure that you carefully follow the supplier's instructions to guarantee optimum performance. By focusing on setup and maintenance procedures, you can optimize the efficiency and life-span of your heavy equipment, inevitably conserving time and money in the long run.

Cost-Effectiveness of Aftermarket Parts

Appropriate setup and routine maintenance are fundamental elements for hefty machinery proprietors aiming to examine the cost-effectiveness of aftermarket parts for their devices. While original equipment manufacturer (OEM) parts are understood for their high quality, aftermarket components provide an even more cost-effective solution without jeopardizing efficiency. The cost-effectiveness of aftermarket components ends up being obvious in various means. Aftermarket components are generally much more inexpensive ahead of time, enabling proprietors to accomplish savings on initial purchase costs. Additionally, these parts frequently offer similar efficiency to OEM parts, making sure that the equipment his explanation runs successfully without the requirement for costly substitutes. Moreover, the accessibility of aftermarket parts from a large range of vendors promotes competitors, causing affordable rates and additional price financial savings for proprietors. By meticulously examining the high quality and compatibility of aftermarket parts with their machinery, proprietors can strike an equilibrium between cost-effectiveness and efficiency, inevitably optimizing the efficiency and longevity of their heavy tools.

Taking Full Advantage Of Performance With Aftermarket Upgrades

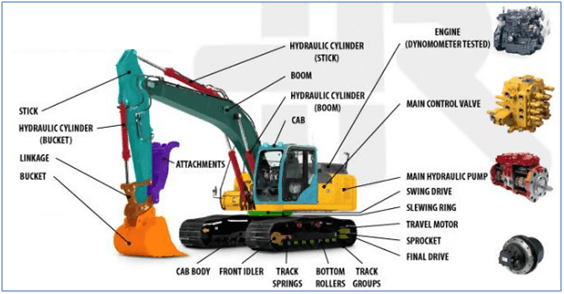

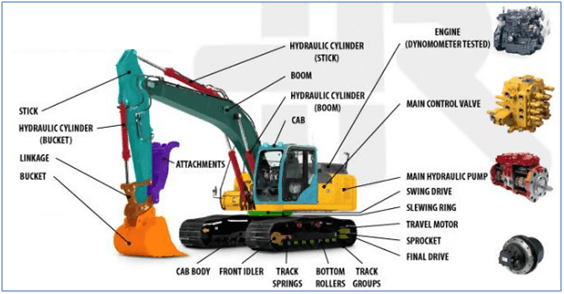

To boost operational efficiency and productivity, hefty machinery owners can properly make best use of performance through strategic utilization of aftermarket upgrades. Aftermarket upgrades use the possibility to tailor heavy machinery to particular operational demands, resulting in boosted performance and output. Updating parts such as engines, transmissions, hydraulic systems, and tracks can substantially improve the overall effectiveness of the machinery.

On a regular basis assessing the performance of hefty machinery and identifying locations where aftermarket upgrades can be useful is necessary for maximizing efficiency. By investing in quality aftermarket components and upgrades, equipment owners can attain greater degrees of efficiency, inevitably causing set you back savings and improved functional outcomes.

Final Thought

To conclude, aftermarket parts use various advantages for heavy machinery proprietors, consisting of cost-effectiveness, boosted efficiency, and personalization choices. By picking the ideal aftermarket components, adhering to proper setup and upkeep treatments, and making the most of upgrades, heavy equipment proprietors can improve their tools's efficiency and durability. Buying aftermarket parts can inevitably result in boosted productivity and reduced downtime, making it a beneficial consideration for proprietors aiming to maximize their machinery procedures.

Owners of heavy equipment can delight in countless benefits by choosing for aftermarket components over initial tools maker (OEM) parts. Aftermarket components are commonly extra inexpensive find more info than OEM parts, permitting machinery proprietors to reduce maintenance and repair service expenses without compromising on quality. By meticulously assessing the quality and compatibility of aftermarket components with their machinery, proprietors can strike an equilibrium between cost-effectiveness and performance, inevitably making the most of the efficiency and longevity of their hefty devices.

In final thought, aftermarket components use numerous advantages for heavy machinery proprietors, consisting of cost-effectiveness, boosted effectiveness, and modification choices. By picking the best aftermarket parts, adhering to proper installation and maintenance treatments, and taking full advantage of upgrades, heavy machinery proprietors can increase their tools's efficiency and longevity.